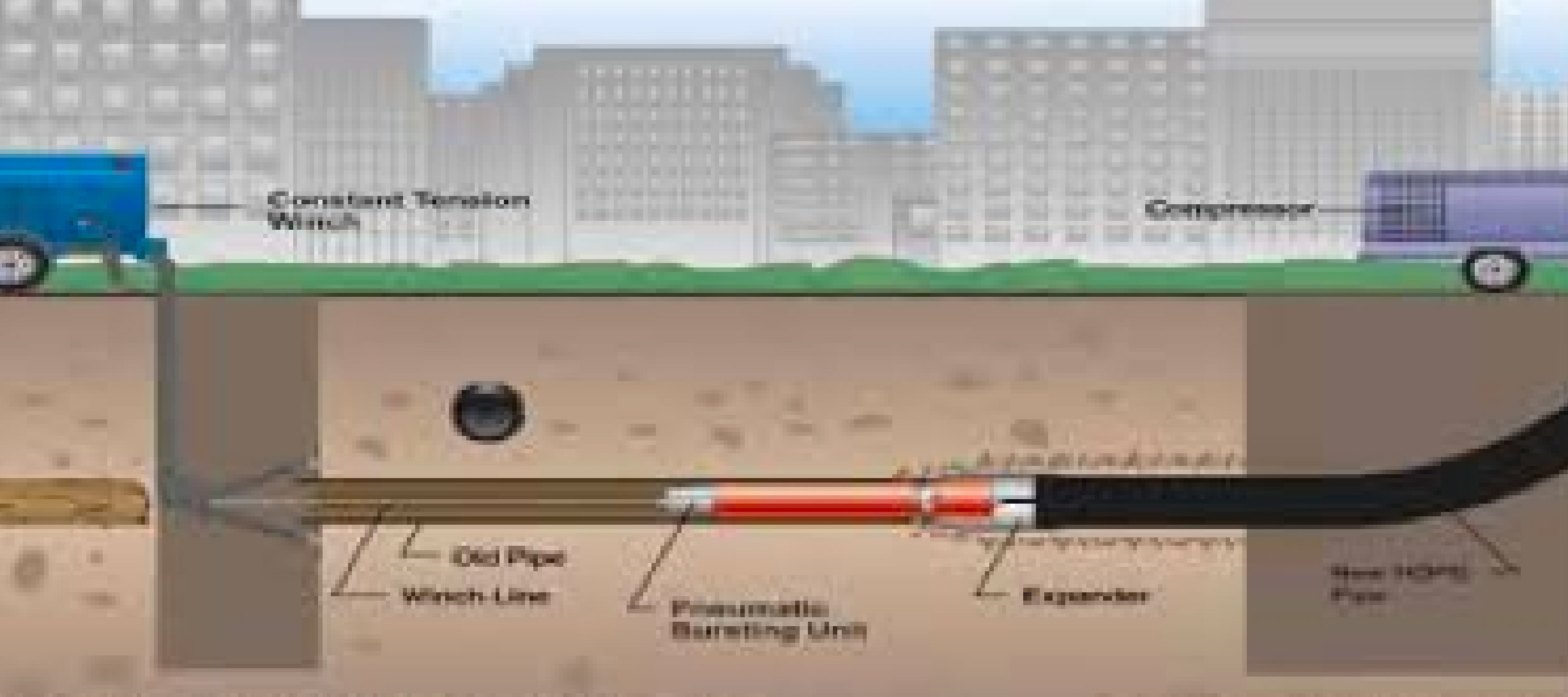

In order to burst the existing pipe, the PRS system can use either static or dynamic (pneumatic) pipe bursting equipment, depending on the particular situation. In the case of the static machines, a custom designed bursting head is pulled through the existing pipe by means of hydraulic power allowing for a smooth vibration-free action to break the existing pipe and instal a new one in its place. Therefore, there will be no danger to any retaining walls, foundations or any other structure to be passed by the bursting head. In other circumstances, the pneumatic equipment is the better application, i.e. only a single launch pit is required thus eliminating the machine pit required for the static machine. To date, we have experienced very few problems with shallow lines (bitumen surfaces will sometimes crack).

Static Bursting Equipment

- Two 45 ton pulling power TRS H45 Hydrahaul pipe bursting machines

- One 65 ton pulling power TRX H65 Hydrahaul pipe bursting machine

- One110 ton pulling power TRX H110 Hydrahaul pipe bursting machine

Dynamic Bursting equipment

Essig Pneumatic hammers:

1x IPM55, 2xIPM130, 1xIPM155, 1xIPM240 and 1xIPM260.

Grundomats:

206mm x 1,130mm x 2, 85mm x 1, 95mm x 1

Bursting Heads:

125mm- 600mm

Compressors:

- XAS 300DD7 Atlas Copco Compressor

- XAS 375DD6 Atlas Copco Compressor

Winches:

- 10 & 5 tonne Bagela Winches.

- 5 tonne Hammer Head Winch.